Description

The second generation PolySurg™ 0603ESDA2-TR2 ESD Suppressors protect valuable high-speed data circuits from ESD damage without distorting data signals as a result of its ultra-low (0.15pF maximum) capacitance.

Features

• Lead free, halogen free materials

• 0603/1608 footprint surface mount device

• Ideal ESD protection for high frequency, low voltage applications

• Exceeds testing requirements of IEC 61000-4-2

• Ultra low capacitance (0.15pF maximum)

• Very low leakage current

• Fast response time

• Bi-directional

Specifications

| Performance Characteristics | Units | Min | Typ | Max |

| Continuous Operating Voltage | Vdc | - - | 14 | 30 |

| Clamping Voltage1 | V | - - | 35 | 60 |

| Trigger Voltage2 | V | - - | 350 | - - |

| ESD Threat Voltage Capability | kv | - - | 8 | 15 |

| Capacitance (@ 1MHz) | pF | - - | 0.10 | 0.15 |

| Leakage Current (@ 12Vdc) | nA | - - | <0.1 | 100 |

| Peak Current | A | - - | 30 Typ. | 45 |

| Operating Temperature | °C | -55 | +25 | +105 |

| ESD Pulse Withstand | # Pulses | 20 | >500 | - - |

1. Per IEC 61000-4-2, 30A @ 8kV, Level 4, contact discharge, measurement made 30ns after initiation of pulse.

2. Trigger measurement made using Transmission Line Pulse (TLP) method.

Applications

• Computers and peripherals • HDTV Equipment

• Blu-Ray/DVD players • A/V Equipment

• Satellite and HD radio • Cell phones

• PDAs • Digital still cameras

• Digital camcorders • MP3 / Multimedia players

• Set top Boxes • External storage

• DSL Modems • GPS

• High speed data ports

- USB 2.0/3.0

- IEEE 1394

- IEEE 1394

- High speed ethernet

- DVI

- DVI

- Infiniband®

- HDMI

- HDMI

Part Numbering System:

Packaging Code

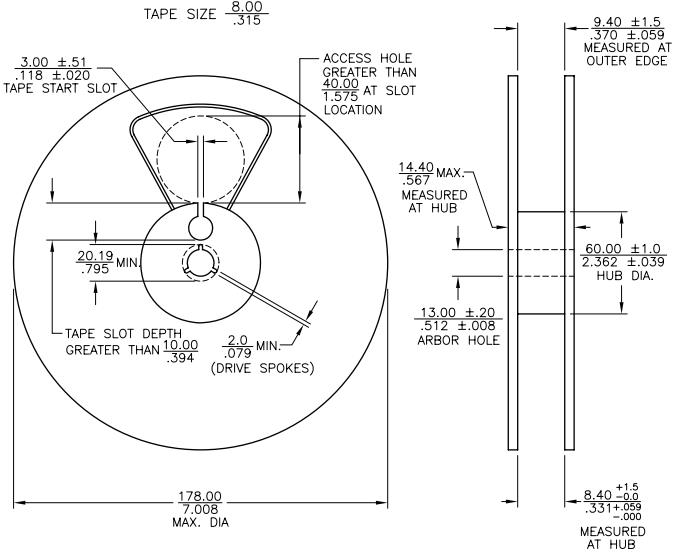

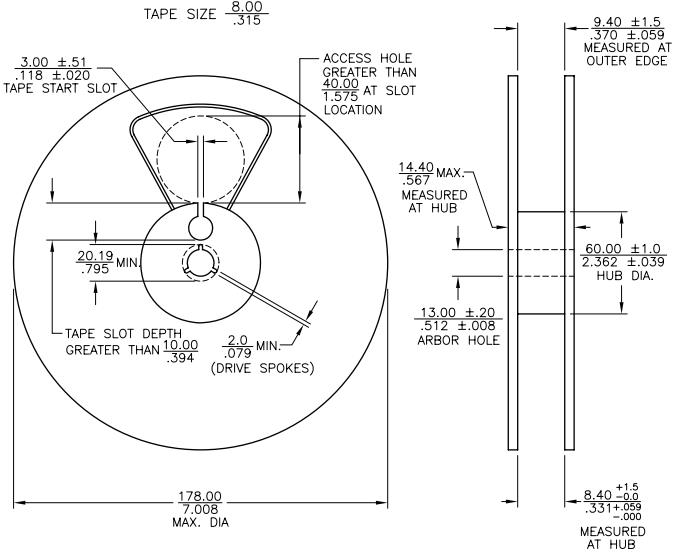

| Package Code Suffix | Description |

| TR2 |

5000 pieces in paper tape on 7 inch diameter (178mm) reel per EIA Standard 481 |

Device Marking

PolySurg™ ESD Suppressors are marked on the tape and reel packages, not individually. Since the product is bi-directional and symmetrical, no orientation marking is required.

Design Consideration

The location in the circuit for the 0603ESDA2-TR2 Series has to be carefully determined. For better performance, the device should be placed as close to the signal input as possible and ahead of any other component. Due to the high current associated with an ESD event, it is recommended to use a “0-stub” pad design (pad directly on the signal/data line and second pad directly on common ground).

Processing Recommendations

The 0603ESDA2-TR2 Series currently has a convex profile on the top surface of the part. This profile is a result of the construction of the device. They can be processed using standard pick-and-place equipment. The placement and processing techniques for these devices are similar to those used for chip resistors and chip capacitors.

Environmental Specifications:

• Coating bond strength: ASTM D3359-83, Method A, Section 6. Note: the device coating is not scored.

• Chemical resistance: ASTM D-543, 4 hrs @ 40°C, 3 solutions (H2O, detergent solution, defluxer).

• Humidity(steady state): MIL-STD-883, method 1004.7, 85% RH, 85°C, 240 hrs.

• Thermal shock: MIL-STD-202F, method 107G, -65°C to 125°C, 30 min, 5 cycles.

• Vibration: MIL-STD-202F,method 201A,(10 to 55 to 10Hz, 1 minute cycle, 2 hrs. each in X-Y-Z axis).

• Solder leach resistance and terminal adhesion per EIA-567.

• Solderability per MIL-STD-202, Method 208 (95% coverage).

• Full load voltage: 14.4Vdc, 1000hrs., 25°C.

• Operating temperature characteristics: Electrical testing at

+105°C and -55°C.

Dimensions - mm (in)

Recommended Pad Layout - in (mm)

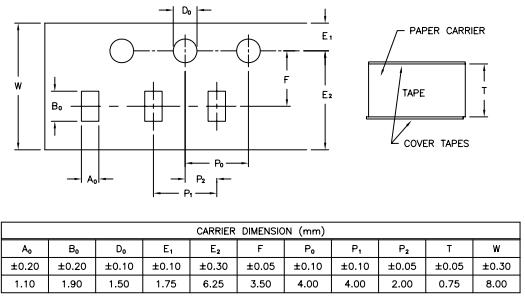

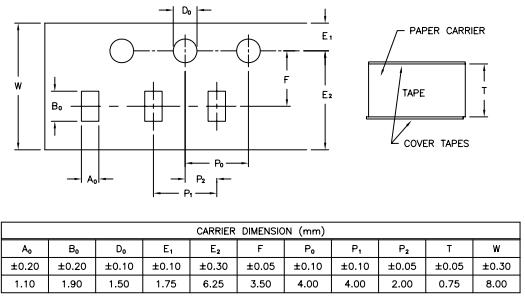

Tape and Reel Specifications - mm (in)

Recommended Pad Layout - in (mm)

Tape and Reel Specifications - mm (in)

Soldering Recommendations

• Compatible with lead and lead-free solder reflow processes

• Peak temperatures and durations:

- IR Reflow = 260°C max for 30 sec. max. Capable of 3X reflow.

- Wave Solder = 260°C max. for 10 sec. max.

- Hand Soldering = 350°C max. for 5 sec. max.

Recommended IR Reflow Profile

| Profile Feature | Sn-Pb Eutectic Assembly | Pb-Free Assembly |

|

Preheat & Soak Temperature min (Tsmin) |

100°C | 150°C |

| Temperature max (Tsmax) | 150°C | 200°C |

| Time (Tsmin to Tsmax) (ts) | 60-120 seconds | 60-120 seconds |

| Average ramp-up rate (Tsmax to Tp) | 3°C/second max. | 3°C/second max. |

| Liquidous temperature (TL) | 183°C | 217°C |

| Time at liquidous (tL) | 60-150 seconds | 60-150 seconds |

| Peak package body temperature (Tp)* | See classification temp in Table 4.1 | See classification temp in Table 4.2 |

| Time (tp)** within 5°C of the specified classification temperature (Tc) | 20** seconds | 30** seconds |

| Average ramp-down rate (Tp to Tsmax) | 6°C/second max. | 6°C/second max. |

| Time 25°C to peak temperature | 6 minutes max. | 8 minutes max. |

|

* Tolerance for peak profile temperature (Tp) is defined as a supplier minimum and a user maximum. ** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum. |

||

SR-5F Series Fast-Acting Submin

SR-5F Series Fast-Acting Submin

TDC Series 1/4"x1-1/4" Glas

TDC Series 1/4"x1-1/4" Glas

CC06H Series High I2t Chip™ 0

CC06H Series High I2t Chip™ 0

GMC Series 5x20mm Medium Time-D

GMC Series 5x20mm Medium Time-D

SR-5 Series Time-Delay Subminia

SR-5 Series Time-Delay Subminia

0402ESDA-MLP1 PolySurg™ ESD S

0402ESDA-MLP1 PolySurg™ ESD S

S505H Series 5x20mm Time-Delay

S505H Series 5x20mm Time-Delay

1025FA Series Fast-Acting Brick™

1025FA Series Fast-Acting Brick™

ATM Low-Profile Fast-Acting Aut

ATM Low-Profile Fast-Acting Aut

GBB Series 1/4" x 1 1/4" Ve

GBB Series 1/4" x 1 1/4" Ve